IC Plant

DETAILS OF OUR INVESTMENT CASTING PLANT

Further to the Company Profile, we give below some details of our Investment Casting plant. We make Investment castings in metals like Stainless Steel, Alloy Steel, Cast Iron & S. G. Iron.

The plant consists of 5 main areas:

Wax room

Shell room

De-waxing area

Shell firing, melting and pouring area

Fettling and finishing

A brief description of the machinery in the above areas:

Wax room

Wax melter, 3 wax injection machines and Assembly tables. Our capacity is about 10 tons per month. All the wax injection machines are PLC controlled and fully automatic.

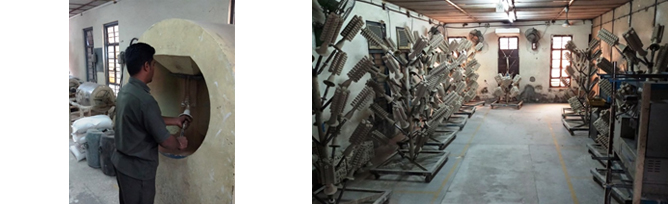

Shell Room

Temperature and humidity controlled atmosphere. This area consists of shell building equipment like slurry mixers, slurry pots, stucco rainfall machines for the primary & secondary coats, fluidised beds for the subsequent coats and trolleys for shell hanging and drying. This is a fully air-conditioned area.

De-waxing

We have state-of-the-art equipment for de-waxing as well as a wax recovery system.

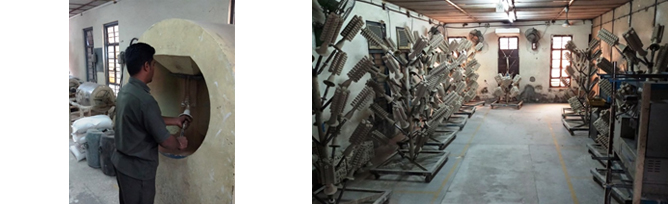

Shell firing, melting and pouring

We have an automatic temperature controlled diesel fired shell firing furnace, and two induction furnaces for melting. One induction furnace is of 50 kg. capacity, which has been reserved for steels. We also have a 35 kg. melting coil, which can be fitted on to the furnace for cast iron and S. G. Iron melting. We have a micro-processor based pyrometer for molten metal temperature measurement and a ferro-lab for instant analysis of C and Si. We get all chemical analyses done from a near-by outside source, which is in fact a Govt. of India agency, and hence very reliable. Apart from this, many reliable spectro-analysis facilities are available in our immediate vicinity. We will be installing our own spectrometer very soon.

Fettling and finishing

This consists of a pneumatic knock-out machine, chemical de-shelling equipment, endless belt grinders, a shot blasting machine and other standard equipment like abrasive cut-off, grinders, die-grinding sets, etc.

Heat Treatment

We supply castings in the heat treated condition if required by the customer. Annealing or normalising is a standard process that is carried out in-house, as is Solution Annealing in case of some Stainless steels. Other heat treatment such as hardening and tempering is out-sourced to reliable heat treatment facilities nearby.

Compressors

Pressurised or compressed air, a very important requirement for many of our equipments, is provided by 3 compressors totalling 30HP, the latest of which is a very modern computerised 15 HP Screw compressor, the other two being reciprocating compressors.

Generating Set

In case of failure of electricity, we have a stand by diesel generating set, which is enough to run our air conditioners, the shell room and some other equipment so that production does not suffer substantially.

Dies or moulds

We get dies (moulds) made from reliable sources in and around Kolhapur, Pune and Mumbai.

Tolerances

We maintain the usual tolerances that are specified for Investment castings, for example, we can supply castings within an accuracy of + 0.12 mm per 25mm or part there-of and in multiples of these values thereafter. We follow the essence of IS:11166:1993 & IS:11709:2007 for matters related to dimensional & mass accuracies, etc. and other technical delivery conditions.

Weight range

Our manufacturing range is from a few grams upto 7-8 kgs. per piece. The smallest casting that we have developed is 1.5 grams and the heaviest is 7 kg. We have limited ourselves presently to manufacturing castings with weights ranging from a few grams up to 1 kg. per piece.

Machining

We can and are already supplying certain castings in the machined condition. We have strategic tie-ups with conventional and CNC machining vendors in Kolhapur and Pune.